島根県の環境機械装置

Environmental machinery and equipment from Shimane Prefecture

This section introduces environmental machinery and equipment manufactured in Shimane Prefecture in Japan.

These are products which solve global environmental problems such as water treatment and water purification, biomass and organic waste treatment, improvement of soil and air environments, recycling, waste treatment, and dismantling.

If you have any questions about a product, please contact the manufacturer directly or the Shimane Prefectural Government E-mail: kaigai-tenkai@pref.shimane.lg.jp

KDS Separator SLIT SAVER

KDS Separator SLIT SAVER

Clog-free solid-liquid separation equipment

This product executes solid-liquid separation by running a mixture of solid and liquid over a group of continuously arranged oval plates. It also has a mechanism to convey solid contents and prevent clogging as the oval plates rotate between numerous slits. It can also be used as a dehydrator by attaching a simple press plate. Compared to other dehydrators, it is superior in maintainability and lower in product price. Its domestic sales record is approximately 800 units, and overseas approximately 50 units. We have records of application for all types of wastewater.

(Head Office in Japan)

Kendensha Co., Ltd.

1372-15 Nagahamacho, Izumo, Shimane

TEL +81-853-28-1818 FAX +81-853-28-2858

http://kendensha.com/bin/index.cgi(外部サイト)

(Subsidiary in Thailand)

C.C.KENDENSHA Co., Ltd

29Moo8 Saladaeng 11Rd.,Saladaeng Bangnampreow Chachoengsao 24000 Thailand

TEL +66-2-988-2334 FAX +66-2-988-2337

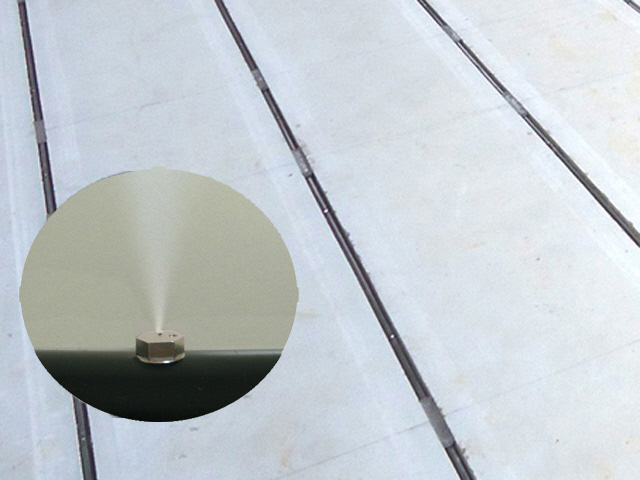

Composting Equipment “Easy Jet”

Composting Equipment “Easy Jet”

Clogging prevented with a special nozzle, and no turning necessary with high-pressure air 50 times stronger than a blower

By sending air from a special nozzle at 50 times the pressure of a conventional blower, it raises the fermentation temperature quickly and reduces the processing period dramatically. It can be installed in existing facilities to help reduce turning work as well as foul odors.

It supplies the enzymes necessary for fermentation evenly without uneven ventilation or clogging, and improves the compost quality.

We have business with customers in various industries such as waste disposal companies, government agencies, livestock and agricultural corporations. We hope to continue to support our customers in Japan and overseas with our unique development capabilities and proposals, taking advantage of our past delivery experience and results.

MIRAIE Co.,Ltd.

250-167 Yadacho, Matsue, Shimane

TEL +81-852-28-0001 FAX +81-852-31-3981

https://miraie-corp.com/(外部サイト)

Biological Deodorization System

Biological Deodorization System

A new deodorization system which utilizes porous glass foam as the base deodorization material

It delivers the highest level of deodorization performance as a system adopting a biological deodorization method, and suffers almost no performance deterioration.

- It suppresses the construction cost since the installation area for the deodorization facility is small, and water expenses are also minimized thanks to the circulating water system.

- A low-pressure blower can be used to blow air and cut electricity expenses by 20 to 50%.

- The difference in maintenance costs is addressed as it needs no replacement semi-permanently once it is installed.

We have business with customers in various industries such as waste disposal companies, government agencies, livestock and agricultural corporations. We hope to continue to support our customers in Japan and overseas with our unique development capabilities and proposals, taking advantage of our past delivery experience and results.

MIRAIE Co.,Ltd.

250-167 Yadacho, Matsue, Shimane

TEL +81-852-28-0001 FAX +81-852-31-3981

https://miraie-corp.com/(外部サイト)

Heaterless Hot Air Blower

Heaterless Hot Air Blower

A new type of hot air blower that generates hot air using frictional heat,helping solve issues related to composting during the winter.

● No heater is used, meaning hot air can be generated without affecting the electricity bill.

● Suited to a wide variety of situations, including heating raw compost materials and drying compost.

● High pressure air flow of 40 kPa (maximum static pressure). Capable of drying even viscous raw materials.

● Features casters and is easily transported.

● Hot air is generated in tens of seconds after startup.

● Can also be connected to a blower.

We have customers in various industries, such as waste treatment companies, government offices,businesses in the livestock industry, and agricultural corporations. Our aim is to continue to support our customers in Japan and overseas by utilizing our unique development capabilities and proposing optimal solutions, building on our past experience and delivered results.

MIRAIE Co.,Ltd.

250-167 Yadacho, Matsue, Shimane

TEL +81-852-28-0001 FAX +81-852-31-3981

https://miraie-corp.com/(外部サイト)

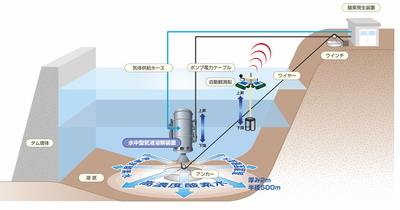

WEP System

WEP System

A water environment preservation system which efficiently supplies a high concentration of oxygen to oxygen-poor water

The WEP System is a system designed to solve water quality problems caused by poor oxygen, in which the oxygen level in the water of dams and lakes becomes extremely low.

The WEP System consists of an underwater apparatus and a land device. The land device concentrates oxygen from the atmosphere to produce oxygen gas with high purity. The oxygen gas produced is supplied to the underwater liquid-gas dissolving apparatus, and forms highly concentrated oxygen water as the oxygen dissolves into the poor-oxygen water.

The WEP System has been adopted mainly in dams in Japan. We have begun expansion of our business overseas in recent years, with plans to expand into China, India and other countries. We are working on the popularization of the WEP System in order to preserve water environments around the world.

Matsue Doken Co., Ltd.

2-3-5 Gakuenminami, Matsue, Shimane

TEL +81-852-24-5478 FAX +81-852-20-0487

https://www.matsue-doken.co.jp/(外部サイト)

Granulator P71KG

Granulator P71KG

Large, low-speed granulator equipped with the largest motor in the industry

Plastic waste has become a global problem. Regulations on plastic waste treatment are expected to be tightened both in Japan and overseas in the future.

P71KG is a large granulator designed with consideration of workability, safety and cleanliness required when recycling plastics in a molding plant.

- A low-speed granulator equipped with a 5.5 kW motor, the largest in the industry.

- The cleaning period is reduced by adopting a casing structure which is divided into three sections.

- Although it is designed for sprue runner processing, it is also possible to granulate products depending on the shape and injected amount.

- While it is a large machine, it does not generate miscuts, which are most characteristic of low-speed granulators, and supplies granulated particles with low powder generation.

DMG MORI Castech Co.,Ltd.

1378 Otsucho, Izumo, Shimane

TEL +81-853-21-3344 FAX +81-853-21-3349

http://dmgmori-castech.com/(外部サイト)

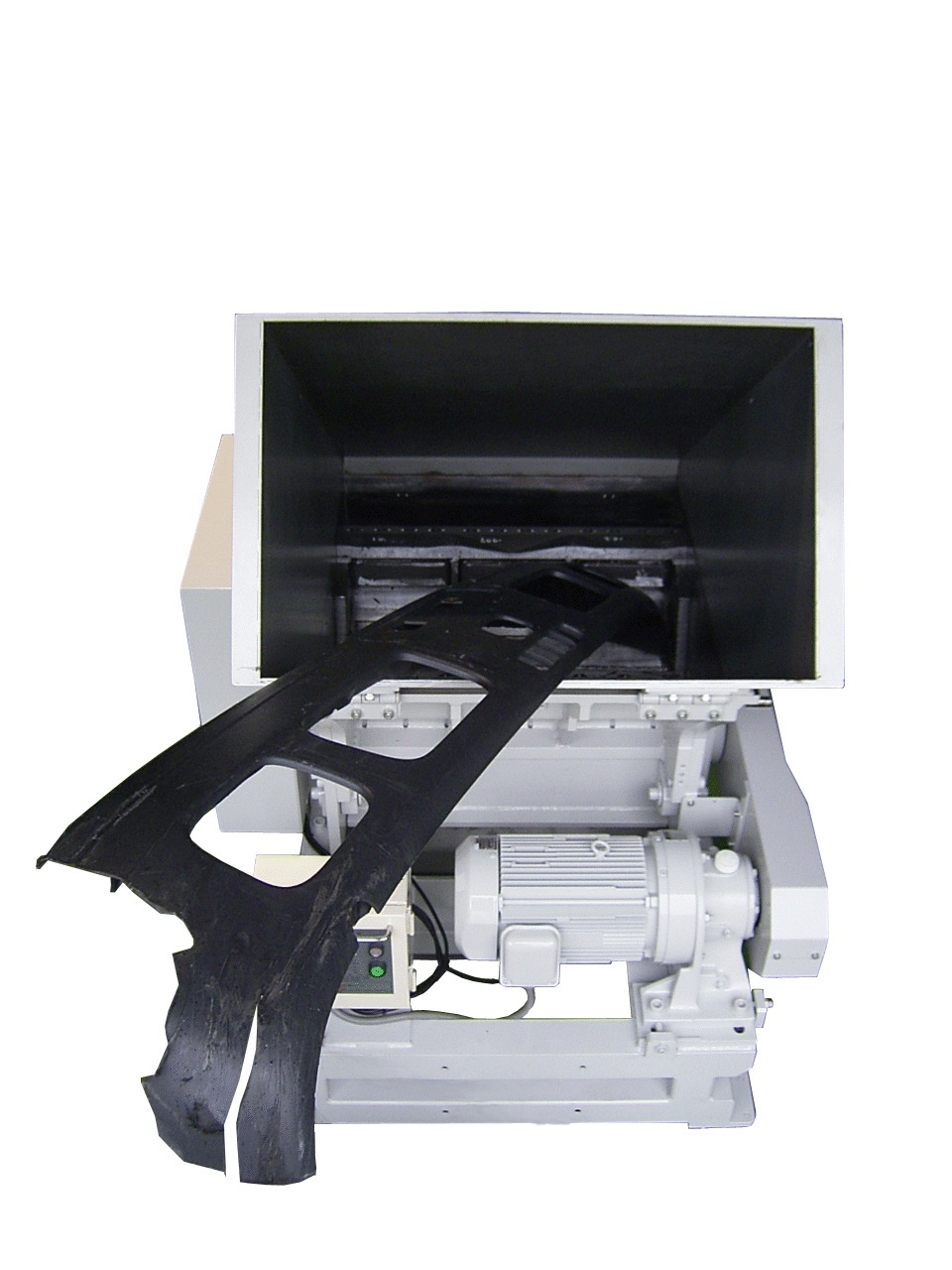

Crusher-Granulator PF72

Crusher-Granulator PF72

Combines the functions of a crusher and a granulator into 1 unit

Plastic waste has become a global problem. Regulations on plastic waste treatment are expected to be tightened both in Japan and overseas in the future.

The PF72 conducts processes from crushing to granulation of large waste products generated in a molding plant in 1 unit, and helps make effective use of resources.

- It securely crushes using a crushing rotor with a wide pocket. The cutting process prior to injection is not necessary even for long articles.

- Low speed rotation reduces the impact noise during crushing.

- A compact machine size of W1,110 * D1,194 * H1,702 mm having a large granulation chamber of 642 * 558 mm. The injection height is 1,382 mm, which has been designed taking into consideration the usability.

- Energy-saving design with a motor capacity of 5.5 kW.

- Ideal for granulation of automobile interior parts and household electrical appliance parts.

DMG MORI Castech Co.,Ltd.

1378 Otsucho, Izumo, Shimane

TEL +81-853-21-3344 FAX +81-853-21-3349

https://dmgmori-castech.com/(外部サイト)

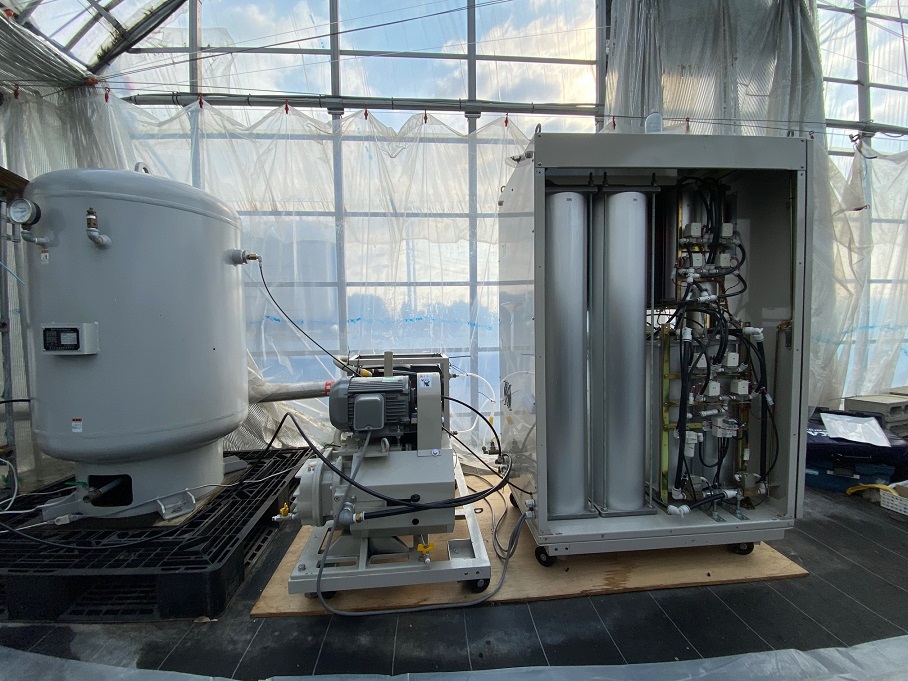

Zeo Collect

Zeo Collect

A device to collect and concentrate CO2 from the atmosphere using natural zeolite produced in Shimane Prefecture

“Environment-friendly application of CO2 in next-generation agriculture”

This device can collect CO2 from a concentration at 400 ppm in the atmosphere and concentrate it to 4,000 ppm or higher (10,000 ppm at maximum).

- Continuous production of high-concentration CO2 gas

- Reduction in running costs by only requiring electricity costs

- Leads to the promotion of photosynthesis, improved growth and quality of crops

- Can be applied throughout the year with piping established at the base of the plant (leaf base)

- No use of heat sources including fossil fuels

- Contributes to the prevention of global warming by using only CO2 from the atmosphere

For more information, click here. Interviws

For more information, click here. Interviws

Daifuku Kougyo, Inc.

2-7 Edaotsucho, Izumo, Shimane

TEL +81-853-21-4151 FAX +81-853-21-4152

https://www.daifuku-izumo.co.jp/(外部サイト)

Hydro Vanguard, a Flexible Wastewater Treatment Device

Hydro Vanguard, a Flexible Wastewater Treatment Device

A wastewater treatment device that can be assembled and disassembled,making it easy to move and install.

This is a flexible wastewater treatment device that can be assembled and disassembled. It can be stored compactly and transported using a kei car. Unlike conventional models made with steel, this device can be transported anytime and anywhere and can be assembled on-site in about 20 minutes. The water treatment capacity is 2 m3/h. When used in combination with zeolite produced in Shimane Prefecture and environmental restoration materials manufactured by our company, the device can purify groundwater mixed with hazardous substances. It is suited for places where short-term wastewater treatment is required, such as wastewater treatment after cleaning tires at construction sites and wastewater treatment in emergencies.

Daifuku Kougyo, Inc.

2-7 Edaotsucho, Izumo, Shimane

TEL +81-853-21-4151 FAX +81-853-21-4152

http://www.daifuku-izumo.co.jp/(外部サイト)

お問い合わせ先

しまねブランド推進課

〒690-8501 島根県松江市殿町1番地

TEL:

0852-22-6397(物産企画係・物産振興推進スタッフ)

0852-22-5284(流通係・販路拡大係)

0852-22-5633(海外展開支援室)

FAX:

0852-22-6859(物産企画係・物産振興推進スタッフ・流通係・販路拡大係)

0852-22-6750(海外展開支援室)

メール:

brand@pref.shimane.lg.jp